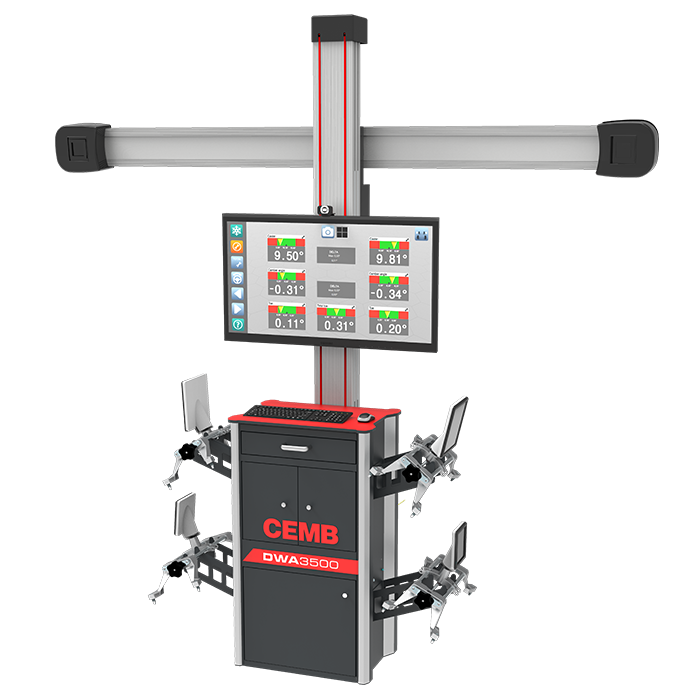

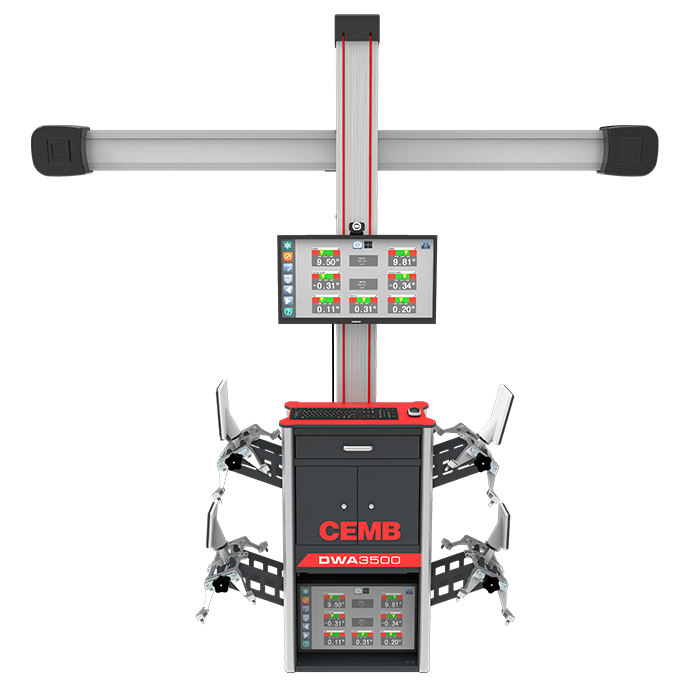

Description

from £53.01 p/w based on a 5 year lease

contact sales on 01322 666 432

- Bluetooth 3D sensor heads transfer data between sensors and console.

- Control unit with PC, 22” TFT monitor, keyboard, printer, and automatic battery charger.

- Mobile control unit for storage of camera heads and clamps.

- Guided procedure and adjustment software with 3D animated pictures.

- Megapixel lenses – 3D solid state targets.

- Operating system compatiable with ADAS calibration.

- 2 years open databank update from the first installation date.

- Shoot and go – Compatible with number plate recognition for fast and accurate set up of vehicle data.

- ALIGNMENT CONNECT app access (STDA141.)

- Lift compensation- Allows the system to be moved between vehicle lifts.

Motorized manual camera beam

The 3D camera support beam is motorized and fully automated. Camera beam height is automatically adjusted to the height of lift. The camera beam position is studied to optimize the available space.

Advanced software

Features very clear and userfriendly graphics. The software system, entirely developed by CEMB, guides the user through all the alignment operations. 3D technology detects all alignment parameters, included wheel diameters, that identify eventual deflated wheels and dimensions such as track, wheelbase and diagonals to identify damages due to crashes. Some of the main innovations are: single wheel lifted run-out in case of restricted space or lifts with steps, measurement with 2 targets for long vehicles, caster trail, scrub angle and audit.

Dedicated Electronics

The system features an industrial type computer, Windows 10 based, solid state SSD Sata, USB interface, webcam and software and database automatic update through wifi connection. No moving parts (DVD/CD) that can cause problems. Direct Shut-Down technology.

Database

The new vehicle model ranking system allows a rapid and clear selection of the different vehicles. The CEMB database contains more than 55.000 vehicles and is constantly updated.